Quality

Consistent with the company's purpose, Nav Indus Food Machines Pvt. Ltd. constantly strives to improve the quality of the industries It serves through excellence in all facets of its activities. We are committed to creating value for all our customers by continually improving our systems and processes through innovation, involving all the ideas from our valued customers. This policy has formed the basis of our Quality Control Process. Every product is put through a series of quality checks, before the actual delivery, and is packed with specialized packaging materials, protecting them from any potential damage during transit.

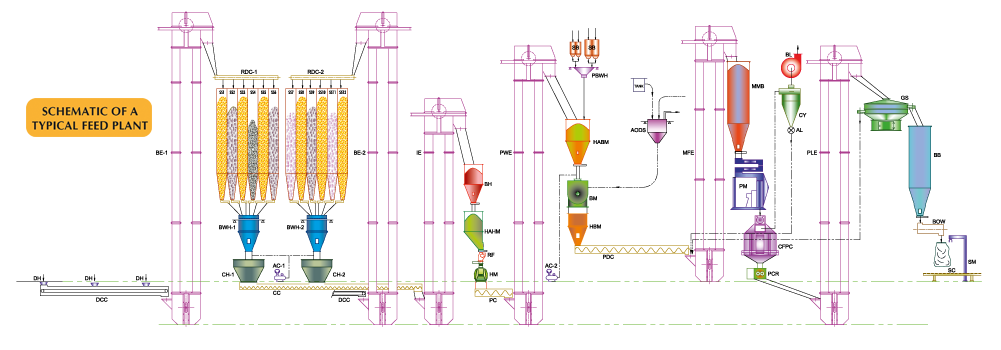

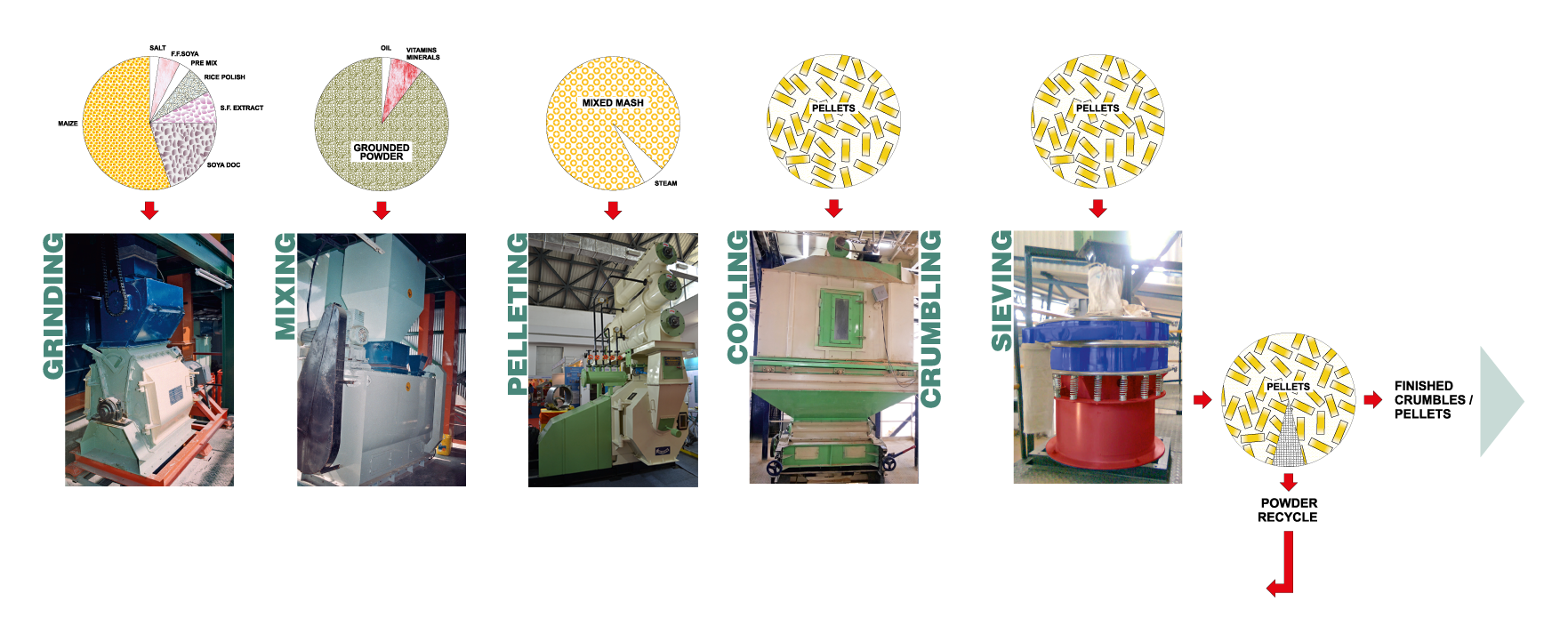

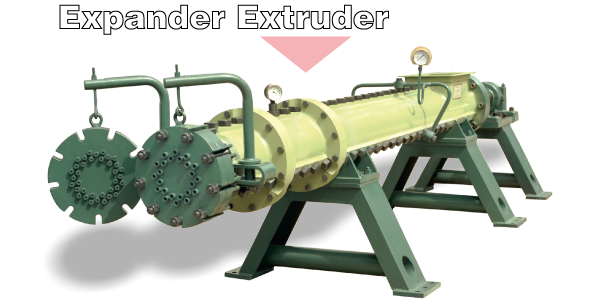

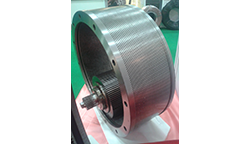

Infrastructure

Nav Indus Food Machines Pvt. Ltd. is empowered by a modern infrastructural setup, comprising of a team of experienced and skilled engineers and technicians as well as state-of-the-art manufacturing plants. All the departments and their respective functions are integrated in the most professional manner so that quality standards are not compromised and they meet global standards and customer expectations. We are headed by professionals who have in depth knowledge and understanding of the industry. The logistic professionals ensure hassle free shipments and clearances by the authorities and thus, guarantee timely delivery of the consignment

After Sales Service

To any Industry, service is an important aspect, to ensure prompt assistance to a customer, as and when, it is required. We have available with us experienced engineers, who could be deputed at short notice. Beside, they also make periodical visits to our installations. We have established this `service cell’ comprising of engineers experienced in maintenance, with a view to ensure prompt and timely service to our customers.